FOOTSTEP POWER GENERATION USING PIEZO ELECTRIC TRANSDUCERS

Electrical and Electronics Project by Ravi Devani

ABSTRACT

Man has needed and used energy at an increasing rate for the sustenance and

well-being since time immemorial. Due to this a lot of energy resources have

been exhausted and wasted. Proposal for the utilization of waste energy of foot

power with human locomotion is very much relevant and important for highly

populated countries like India where the railway station, temples etc., are

overcrowded all round the clock .When the flooring is engineered with piezo

electric technology, the electrical energy produced by the pressure is captured

by floor sensors and converted to an electrical charge by piezo transducers,

then stored and used as a power source. And this power source has many

applications as in agriculture, home application and street lighting and as energy

source for sensors in remote locations.

Keywords—Piezoelectricity, PZT, PVDF, Inverter, PIC16F873

INTRODUCTION

At present, electricity has become a lifeline for human population. Its

demand is increasing day by day. Modern technology needs a huge amount of

electrical power for its various operations. Electricity production is the

single largest source of pollution in the whole world. At one hand, rising

concern about the gap between demand and supply of electricity for masses has

highlighted the exploration of alternate sources of energy and its sustainable

use. On the other hand, human population all over the world and hence energy

demand is increasing day by day linearly. Accordingly, it is an objective of

the present invention to provide a method of electrical power generation from

this ever increasing human population that does not negatively impact the

environment. This technology is based on a principle called the piezoelectric

effect, in which certain materials have the ability to build up an electrical

charge from having pressure and strain applied to them. Piezoelectricity refers

to the ability of some materials to generate an electric potential in response

to applied pressure. Harvesting of energy which means energy is already

available, but is going to waste if not utilized. Embedded piezoelectric

material can provide the magic of converting pressure exerted by the moving

people into electric current.

RESEARCH ELABORATIONS

STUDY OF PIEZO MATERIALS

Piezoelectric ceramics belong to the group of

ferroelectric materials. Ferroelectric materials are crystals which are polar

without an electric field being applied. The piezoelectric effect is common in

piezo ceramics like PbTiO3, PbZrO3, PVDF and PZT. The main component of the

project is the piezoelectric material. The proper choice of the piezo material

is of prime importance. For this, an analysis on the 2 most commonly available

piezoelectric material - PZT and PVDF, to determine the most suitable material

was done. The criterion for selection was better output voltage for various

pressures applied. In order to understand the output corresponding to the

various forces applied, the V-I characteristics of each material namely, PZT

and PVDF were plotted. For this the Piezo transducer material under test is

placed on a Piezo force sensor. Voltmeters are connected across both of them

for measuring voltages and an ammeter is connected to measure the current. As

varying forces are applied on the Piezo material, different voltage readings

corresponding to the force is displayed. For each such voltage reading across

the force sensor, various voltage and current readings of the Piezo test

material are noted.

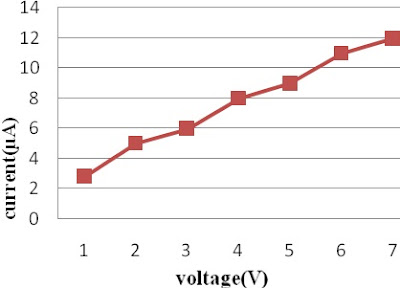

Fig 1: V-I graph of

PVDF material

Fig 2: V-I graph of

PZT

The voltage from PZT is around 2 V where as that of PVDF

is around 0.4V.We can thus conclude that better output is obtained from the PZT

than the PVDF.

STUDY OF CONNECTIONS

Next to determine the kind of connection that gives appreciable voltage and

current necessary, three PZT are connected in series.

Fig .3: PZT in series connection

Electrical and Electronics Project by Ravi Devani

A force sensor and voltmeter is connected to this series combination. As

varying forces are applied on this connection, corresponding voltages are

noted. Also the voltage generated across the series connection and the current

is measured. Similarly the connections are done for parallel and

series-parallel connections are done and the graphs are as in figures 3 and 4.

Fig 4: V-I graph of parallel and series connection

Fig 5: V-I graph of parallel and series combination

It can be seen from the graph that the voltage from a series connection is

good but the current obtained is poor, whereas the current from a parallel

connection is good but the voltage is poor. But this problem is rectified in a

series- parallel connection where a good voltage as well as current can be

obtained.

HARDWARE IMPLEMENTATION

The hardware set up is as shown in figure 6. A tile made from piezo

material is made. The voltage generated across a piezo tile is supplied to a

battery for it to recharge and supply the dc loads. Voltage generated is also

given to an inverter, from where it is supplied to all the ac loads. A LCD is

interfaced to the tile using a PIC microcontroller to display the voltage

generated across the piezo tile.

Fig 6: Hardware setup

WORKING

The

piezoelectric material converts the pressure applied to it into electrical

energy. The source of pressure can be either from the weight of the moving

vehicles or from the weight of the people walking over it. The output of the

piezoelectric material is not a steady one. So a bridge circuit is used to

convert this variable voltage into a linear one. Again an AC ripple filter is

used to filter out any further fluctuations in the output. The output dc

voltage is then stored in a rechargeable battery. As the power output from a

single piezo-film was extremely low, combination of few Piezo films was investigated.

Two possible connections were tested - parallel and series connections. The

parallel connection did not show significant increase in the voltage output.

With series connection, additional piezo-film results in increased of voltage

output but not in linear proportion. So here a combination of both parallel and

series connection is employed for producing 40V voltage output with high

current density. From battery provisions are provided to connect dc load. An

inverter is connected to battery to provide provision to connect AC load. The

voltage produced across the tile can be seen in a LCD. For this purpose

microcontroller PIC16F873A is used. The microcontroller uses a crystal

oscillator for its operation. The output of the microcontroller is then given

to the LCD which then displays the voltage levels.

Fig 7: Schematic representation of the working model

The

inverter used in this circuit uses the IC CD4047. It is used to convert the DC

voltage stored in the battery to AC voltage. IC CD4047 produces two pulse

trains phase shifted by 180°. These pulse trains are used to switch transistors

configured in common emitter mode producing pulse trains of 12V, which is

capable of switching a MOSFET. The sources of the two MOSFETs used in the inverter

circuit are supplied with a 12V supply. When the MOSFETs are switched on by the

outputs of the transistors, two output pulses of 12V are obtained. These pulses

are connected to a step up transformer from whose high voltage side; we obtain

the 220V AC supply.

MAXIMUM THEORETICAL VOLTAGE GENERATED

When a force is applied on piezo material, a charge is

generated across it. Thus, it can be assumed to be an ideal capacitor. Thus,

all equations governing capacitors can be applied to it. In this project, on

one tile, we connect 3 piezo in series.10 such series connections are connected

in parallel. Thus when 3 piezoelectric discs are connected in series, its

equivalent capacitance becomes:

(1) We know, (2) So, (3) Hence, (4) Thus , (5)

Hence, the net voltage generated in series connection is the sum of individual

voltages generated across each piezoelectric disc. Output voltage from 1 piezo

disc is 13V.

Thus, Veq = V1+V2+V3 (6)

= 13+13+13

= 39V

Thus the maximum voltage

that can be generated across the piezo tile is around 39V.

ANALYSIS DONE ON THE PIEZO TILE

People whose weight varied from 40kg to 75 kg were made

to walk on the piezo tile to test the voltage generating capacity of the Piezo

tile. The relation between the weight of the person and power generated is

plotted in figure 8. From the graph it can be seen that, maximum voltage is

generated when maximum weight/force is applied. Thus, maximum voltage of 40V is

generated across the tile when a weight of 75 Kg is applied on the tile.

Fig

8: Weight V/s power graph of piezo tile

CONCLUSION

A piezo tile capable of generating 40V has been devised.

Comparison between various piezo electric material shows that PZT is superior

in characteristics. Also, by comparison it was found that series- parallel combination

connection is more suitable. The weight applied on the tile and corresponding

voltage generated is studied and they are found to have linear relation. It is

especially suited for implementation in crowded areas. This can be used in

street lighting without use of long power lines. It can also be used as

charging ports, lighting of pavement side buildings.

REFERENCES

[1] Vibration Based Energy Harvesting Using Piezoelectric

Material,M.N. Fakhzan, Asan G.A.Muthalif, Department of Mechatronics Engineering,

International Islamic University Malaysia, IIUM,Kuala Lumpur, Malaysia.

[2]

Piezoelectric Crystals: Future Source Of Electricity, International Journal of

Scientific Engineering and Technology, Volume 2 Issue 4, April 2013Third Year

Electronics Engineering, Atharva College of Engineering,

Mumbai, India.

[3] Electricity from Footsteps, S.S.Taliyan, B.B. Biswas,

R.K. Patil and G. P. Srivastava, Reactor Control Division, Electronics &

Instrumentation Group And T.K. Basu IPR, Gandhinagar.

[4] Estimation of Electric Charge Output for

Piezoelectric Energy Harvesting,LA-UR-04-2449, Strain Journal, 40(2), 49-58,

2004;Henry A. Sodano, Daniel J. Inman, Gyuhae Park.

[5] Center for Intelligent Material Systems and

Structures Virginia Polytechnic Institute and State University.

[6] Design Study of Piezoelectric Energy- Harvesting

Devices for Generation of Higher Electrical Power Using a Coupled

Piezoelectric-Circuit Finite Element Method IEEE Transactions on Ultrasonic’s,

Ferroelectrics, and Frequency Control, vol. 57, no. 2, February 2010.

[7] Meiling Zhu, Member, IEEE, Emma Worthington, and

Ashutosh Tiwari, Member, IEEE.

Electrical and Electronics Project by Ravi Devani

No comments:

Post a Comment