WIRELESS

LOAD CONTROL DEVICE USING GSM MODULE

ABSTRACT

This paper presents Wireless Load Control Device (WLCD) using GSM module.

The WLCD consists of PIC18F4550, GSM Module, relay circuit, keypad, and LCD.

PIC18F4550 is used as a microcontroller to process the received data and then

the output signal is sent for on/off relay switch. The users can on/off load in

two ways, either keypad or short message service (SMS). The WLCD can control three

loads and the current status of each load is displayed on the LCD. A working

prototype of WLCD was built to demonstrate the effectiveness and efficiency of

on/off load control through the GSM network.

Keywords: wireless load control device,

PIC microcontroller, 18F4550, GSM module, SIM900B

INTRODUCTION

Nowadays, the innovative technologies have become an integral part of human

life. Various load control method and technology such as power line carrier

(PLC), telephone modem, internet, WIFI, Bluetooth, and

ZigBee were established and developed to facilitate comfortable for humans.

There are many researches about load control method and technology until now.

For example, in 2000, R. C. Luo et al. presented intelligent autonomous mobile

robot control through the Internet. In 2010, X. Liu and W. Wang introduced a

control system of indoor intelligent Lighting which is based on power line

carrier communication. The power line is used to transmit the analogue or

digital signals with high speed. Not only power line technology but also

wireless remote control and GSM network are used to combine for remote the indoor

intelligent lighting and controlling the sensing. Architecture for power

monitoring system using the wireless sensor network technology is proposed in

2011. In 2013, V. Bhatia and P. Whig present the modeling and simulation of

electrical load control system using RF technology. Moreover, V. Bhatia and P.

Whig designed and simulated the smart elevator control system with Security

based on Dual Tone Multi Frequency. R. Makwana et al. tried to study the

comparative of different wireless protocol between ZigBee (over IEEE 802.15.4)

and Bluetooth (over IEEE 802.15.1).

In addition, the microcontrollers are playing a very important role in the

development of the smart systems. The microcontroller is basically a single chip

microprocessor suited for machine controlling and system processing because it

carries out autonomous operations and takes smart decisions. Moreover, the

devices such as air conditioners, power tools, toys, office machines employ

microcontrollers for its operation.

This paper designs and develops the control of electrical loads using GSM

module. PIC18F4550 is used for processing and controlling of the WLCD. By

pressing the keypad on the WLCD, the controllability of the electrical load can

be achieved. Moreover, the users can send the command to remote control the

electrical load and receive the current status of the load by GSM module.

MATERIAL AND METHOD

The complete system of WLCD can be shown in Fig. 1, consists of four major

parts: (1) input command, (2) microcontroller, (3) output display, and (4)

electrical load driver.

Fig. 1: Block diagram of the WLCD

Hardware Implement

Input Command

WLCD can receive the input command in two ways (i.e. keypad or SMS). 3x4

keypad switches are connected to the microcontroller for sending the input

command to control each electrical load. In the other way, the user can

interface with the WLCD by sending the SMS from the mobile phone to its. The

GSM module (SIM900B) is used to receive that SMS from the user via GSM network

and send the data to the microcontroller via RS232 serial port.

Microcontroller

A microcontroller (PIC18F4550) is used as an interface device (input command,

LCD and the electrical load driver). It is a 40-pin dip, low power consumption

and high speed FLASH/EEPROM technology. It consists of 256 bytes EEPROM memory,

35 Input/output, two external clock modes (up to 48MHz), 13 channels of 10-bit

analog to digital converter, and a capture/compare/PWM functions. 7805 voltage regulators

are used to convert 12Vdc to 5Vdc and the output is then given to the

microcontroller and GSM module. The electrical load driver, keypad and LCD are

connected with microcontroller at port A, B and D, respectively.

Output of the WLCD

16X2 LCD is used in the system to display the current status of the WLCD.

Besides the LCD, the user can receive the current status of electrical load by

sending SMS to the WLCD.

Electrical load driver

The electrical load driver includes the opto-isolator and the relay circuit.

The opto-isolator has the function to transmit the output signal from the

microcontroller to the relay circuit. The relay circuit is an interrupting

device designed for shutting on/off the power supply. The relay switch is

designed for the electrical load at 220Vac and 10A. When the WLCD receives the

command, the microcontroller will control the relay switch to on/off the

electric power supply via the opto-isolator. The prototype of hardware implementation

was done as shown in Fig.2.

fig 2. The WLCD prototype

Software Implement

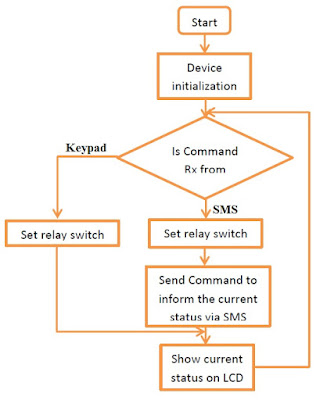

According to the hardware circuit design features, WLCD

controlling program flowchart is introduced as shown in Fig. 3. First, the

system initializes each module, and then turns off all electrical loads. Then, WLCD

started already, the microcontroller sends the command of AT + CMGD = 2 for

clearing the second data storage space in the SIM card of GSM module. When the

user sends the short messages to WLCD, GSM module will send that command to the

microcontroller. After that the microcontroller will turn on/off load according

to the received command and show the current status on the LCD. The microcontroller

sends a command (such as AT+CMGS="+66868273639" and “SW1-ON SW2-ON

SW3-OFF”) to the GSM module for informing the current status to the user. In

the other way, when the received command is sent from the keypad, the WLCD will

operate to on/off the electrical load and show the current status of each electrical

load on the LCD module.

Fig. 3: Flow diagram of WLCD controlling

program

Table 1 shows the control command to control the

electrical loads of WLCD. For example, when the user need to on only SW2, the

command is “*010#”.

Table 1: WLCD control commands

RESULTS

Electrical loads such as fans, bulbs, and computer etc. are tested and controlled

wirelessly by the WLCD. When starting up the program, the LCD will show as Fig.

4(a). Then, three electrical loads can be controlled at a time in the present

system. For example, when the user enters “*000#” to the WLCD using keypad, all

of electrical loads will turn off and the LCD will show the current status as

shown in Fig. 4 (b). Next, the user sends the SMS command (“*111#”) to the

WLCD, the LCD will show the phone number of a user as shown in Fig. 4 (c).

Then, all loads are switched on and the LCD will show the current status of

electrical load as shown in Fig. 4 (d). After that, the microcontroller will

send the current status to the user via SMS as shown in Fig. 4 (e).

(a) Start up the program

(b) Off all electrical load

(c) the number of user who send the command to the WLCD

(d) On all electrical load

(e) SMS send and

receive from WLCD

Fig. 4: the result of WLCD

CONCLUSION

To control the electrical load by wireless communication using GSM module,

the WLCD was constructed. The WLCD is designed to provide three loads (rated of

each load at 220Vac 10A). The electrical loads can be turned on/off by keypad

on WLCD or SMS via GSM network as the command shown in Table 1. The user can

know the current load status by LCD on WLCD or the SMS from WLCD.

The advantage of WLCD can be stated as follows:

- wireless control from remote places,

- ease of operation by using any mobile possible to on/off electrical load,

- the users will get a convenient, and

- time saving.

In addition, this WLCD can be applied to the other systems such as controlling

the pump, motor, etc. In the future work, we will add the electrical measuring

system which can read and send the electrical measuring value such as power and

energy to the user. The system will be designed to increase the current load

more than 10A by using the higher size of the relay. Moreover, the WLCD can be

extended to the desired number of loads by adding the relay circuits and

changing the control commands.

REFERENCES

[1] R.C. Luo, T.M. Chen, and C.C. Yih. Intelligent Autonomous Mobile Robot

Control through the Internet. IEEE International Symposium ISIE. 2000,

1: 6-11.

[2] X. Liu and W. Wang. Indoor Intelligent Lighting Control System Based on

Power Line Carrier Design. 2010 Second WRI Global Congress on Intelligent

Systems (GCIS), 2010, 1: 408-411.

[3] R. V. P. Yerra et al. WSN based power monitoring in smart grids.

Seventh International Conference on Intelligent Sensors, Sensor Networks and

Information Processing (ISSNIP), 2011, 401-406.

[4] V. Bhatia and P. Whig. Modelling and Simulation of Electrical Load

Control System using RF Technology. International Journal of

Multidisciplinary Science and Engineering, 2013, 4(9): 44-47.

[5] V. Bhatia and P. Whig. A Secured Dual Tone Multi Frequency based Smart

Elevator Control System. International Journal of Research in Engineering

& Advanced Technology. 2013, 1(4): 1-5.

[6] R. Makwana et al. Wireless Based Load Control and Power Monitoring

System. International Conference on Energy Efficient Technologies for

Sustainability (ICEETS), 2013, 1207 – 1211.