WIRELESS DATA ACQUISITION FOR PHOTOVOLTAIC POWER SYSTEM

ABSTRACT

This

paper presents a wireless system for monitoring the input and output of the

array in a photo voltaic generation plant. The system comprises of sensors, data

acquisition system, wireless access point and user computer that enable the

users to access the array parameter wirelessly. Description and function of set

up equipment are presented as well as the application program that supports the

system.

INTRODUCTION

Recently,

the number of energy in the world is reaching to concern state. This is caused

by the need of energy is growing very fast. Due to concerns regarding global

warming and air pollution, there has been an international movement in the

promotion of renewable energy technologies for electricity generation, green

energy is one among proposed solutions for these issues. Solar energy is

converted to electricity in a photovoltaic generation plant that contains

photovoltaic array as solar electricity conversion equipment, electrical power

converter, power storage and other supporting equipment. According to operation

mode, photovoltaic generation plants are met in isolation mode, grid

interconnected mode and plant that can operate in both modes. For all of these

modes, there are needs to acquire the input and output parameter of the

photovoltaic array as the generation equipment. The acquired parameters are

used for control action information, generation planning, energy forecasting,

and performance observation or documentation need. Some of the parameters are

irradiance, temperature and array's electrical output. A satisfied data

acquisition system is required for this need.

Related

to acquisition system for photovoltaic performance, Benghanem et ai. have

accomplished a research in which, several instruments are used to detect,

integrate, and record solar energy measurement using both conventional

electronics as well as microprocessor data acquisition system. Further,

Machacek et aI., developed a system for measuring, collecting, analyzing, and

displaying data for 100 W solar energy converter, data acquisition is formed by

NI-6023E plug-in card and feed the rough data to the control program built in a

MATLAB script.

Data

from acquisition system module are needed to produce useful information. The

speed of the process is the important parameter. To accommodate this

requirement, during the past decade, digital control has been widely used.

Digital control, which is determined by application of microprocessors, makes

the sampling and computing process are faster than before. Implementation of

such a system has been done on a dc voltage monitoring and control system for a

wind turbine inverter.

FIg 1. Simplifieddiagramof the Wireless data

acqutsitron for photovoltaic system.

Regarding

with data transmission, Chen,et.al, have studied carrying the acquired signal

from data acquisition module using internet. Java language is used for

designing a dynamic webpage to graphically display various real time waveforms

of the controlled system for multi-user at the same time. The system is

implemented on a small scale wind power generation system equipped with an

EZDSP 2812 controller. An FPGA ECIO is implemented as a bidirectional

communication interface for coordinating the asynchronous data transmission

modes. In this paper, we present a photovoltaic generation monitoring system

for a 5 kWp laboratory scale photovoltaic generation. Temperature, irradiance,

voltage, and current of the array are acquired, processed and then transmitted such

that can be used for reviewing the performance of the generation plant.

Acquired data is transmitted by wireless method using Wi-Fi signal (IEEE 802.11

standard), while microcontroller of PIC 16F877A is used to control the

acquisition system process and a Delphi application program is built to

graphically display the acquired data. Figure 1 show the simplified diagram of

such system.

PV

GENERATIONCHARACTERISTIC FORMONITORING SYSTEM

The

acquisition system is aimed to detect and collect the parameters that indicate

the electrical characteristic of the array and the factors influencing them.

(a)

characteristics on various irradiance at a constant temperature,

(b)

Characteristic on various temperature at a constant irradiance

Fig. 2. V- I characteristic of PV module

As

shown in Figure 2, photovoltaic array characteristic (V-I curve) shows

the dependency of cell current and voltage to irradiance and temperature.

Irradiance contributes to the cell current, the higher irradiance the higher

current draw by array photovoltaic, while the temperature effects to the cell

voltage, the higher temperature the lower voltage appears on the cell terminal.

In Figure 2a, it is shown a set of photovoltaic cell 1-V curve under

varying irradiance at a constant temperature, meanwhile figure 2(b) shows the

one at the same irradiance values, but under varying temperature. Both figures

are also show the point where the multiplication of PV array voltage and

current reaches the maximum value: maximum power point (MPP), at which condition

that the array operates with maximum efficiency and produces maximum output

power. Variation of irradiance and temperature in photovoltaic module is

characterized as short time fluctuation; follows the behavior of atmospheric

condition around plant during time. The effect of this variation is the

unpredictable variation of power output, current and voltage of the plant. An

acquisition system for this condition should consider the phenomenon.

PV

GENERATIONMONITORING SYSTEM

The

PV generation and monitoring system shown in Figure 1, is a diagram of a laboratory

scale system that contains three units photovoltaic array produces three de

voltages of 0 - 150 range. These de voltages is then fed to three single phase

PV inverter respectively to be inverted to ac power before sending to the

utility. Maximum current for each array are lOA de. Array power input in form

of temperature and irradiance and the de output of array are picked up as data

acquired for the monitoring system. Three ACS754 current sensors with maximum

current 50A and sensitivity of 37.8 mV/A are connected to de output of each

solar array, while irradiance and temperature sensor placed around the array.

For voltage acquisition, 1k.o.-1M.o. voltage divider was used, which means 10mV

for every one volt de solar panel output. LM35 temperature sensor which

sensitivity of 10mV/oC is used for measure the ambient temperature of solar

panel. The irradiance is sensed using LDR. Data acquisition diagram is shown in

Figure 3. In order to determine the analog signal from the sensor to be passed

to ADC, which contains eight analog signal from sensors (3 for de current, 3

for de voltage, one for irradiance and the remaining for temperature) dual

eight-channels analog multiplexer DG407B are used. The analog multiplexer was

controlled using microcontroller and passing the multiplexing signal with their

own voltage references. In the ADC block, each analog signal from multiplexer

is digitalized to eight bits digital signal. Eight-bit signal is used caused by

the condition that communication between microcontroller and serial to Ethernet

module uses eight bit data. Thus, voltage reference for ADC is Vrej = resolution

x 28 , where the resolution is equal to sensitivity of each sensor. ADC

operation is also controlled by the microcontroller. In this system, the

microcontroller is employed to run the following function: controlling the

multiplexer for determining the analog signal from the sensor to be passed;

controlling the operation of ADC, and as communication protocol between

Ethernet and the acquisition system. To accommodate these functions, the

low-power consumption PIC 16F877A microcontroller is used. This unit is built

within eight channels 10 bit ADC and an UART connection for serial

communication. Microcontroller serial connection is connected to Wiznet

EGSR7150 in order to convert format data from serial to Ethernet data,

conversion process is reversal. Further, the acquainted data is sent to the

access point to be sent in form of Wi-Fi signal to connected user computer. To

accommodate communication between computer and acquisition system and to

display the result, a computer application program is required.

Fig. 3. Data acquisition system diagram

For

this need, an application program, written in Delphi language is developed.

This program is built to allow the user can interact and control the process

steps in these two subsystems (microcontroller in acquisition system and

displaying process in computer). Communication between computer and acquisition

system is done wirelessly. Communication process involves two application

programs, one is in the computer side and the other is in microcontroller side.

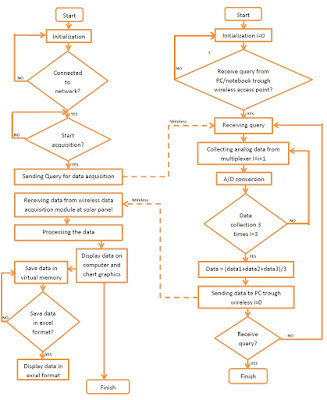

Flowchart of communication between these two applications programs is shown in

Figure 4, which shows two main blocks, indicates the process flow in each side.

First of all, the programs will self-initialize when they are activated. User

can decide whether to acquire data or not. If acquisition data will be done,

program will send a query command to the acquisition program on microcontroller

contains which data to be acquired. Microcontroller in acquisition system

-based on the command query- orders the multiplexer to by-pass the intended

analog signal from the sensors and digitalized them. Analog signal from the

sensors contains high noise, which can degrade the measurement accuracy. To

avoid this, analog signal is picked up and converted three times; their average

is computed and become data to be sent back as acquisition data to user

computer. In user computer, acquisition data is received by Ethernet port.

Application program then processes the data to be displayed and to be saved in

the virtual memory. The displaying application program is shown in Figure 5.

There

are 5 charts that show the measured and calculated parameters. Voltage,

current, and calculated PV array power of whole channel is displayed in one

chart respectively. Each PV array power output is obtained by multiplying the

voltage and current of respective array. The array temperature and irradiance

are displayed separately in others charts. Nominal values of these parameters

are also displayed. To start data acquisition, user must connect the

application to acquisition module by pressing the "Connect to

network" button. Timer setting button is provided to determine measurement

interval of the acquisition data. Prototype ofthe photovoltaic acquisition

system is shown in Figure 6. The left side picture shows layer for power

supply, voltage divider and current sensor, this layer is placed in the bottom

of acquisition compartment. The right side pictures shows layer for the

microcontroller, multiplexer, Vref board and data converter.

Fig. 4. PC and microcontroller software flowchart

Fig.5. Application program appearance

Fig. 6. Prototype of the photovoltaic acquisition

system, (a) upper layer, (b) lower layer

CONCLUSION

A

wireless data acquisition system for photovoltaic generation system that uses

PICI6F877A microcontroller as the main control has been presented.

Implementation of the EGSR7150 Ethernet to serial module and the access point

as Wi-Fi communication tool between acquisition equipment and user computer for

graphically displaying the acquired parameter has work properly as intended.

Implementation of such a system on a laboratory scale photovoltaic generation

shows the practical simplicity, efficient and low cost.

REFERENCES

[I]

Po-Yen Chen; Se-Kang Ho; Wei-Jen Lee; Chia-Chi Chu; Ching-Tsa Pan, "An

Internet Based Embedded Network Monitoring System for Renewable Energy

Systems",Proc. The 7th nternational Conference on Power

Electronics, pp.225-228 , October 22-26,2007.

[2]

M.Benghanem; A. Maafi, "Data Acquisition System for Photovoltaic Systems

Performance Monitoring", IEEE Trans. On Instrumentation and

Measurement, Vo1.47, No.1, pp.30-33, February 2008.

[3]

J. Machacek; z. Prochazka; J. Drapela, "System for Measuring and

Collecting Data from Solar-cell Systems",Proc.9th International

Conference Electrical Power Quality and Utilization, Barcelona, 9-11

October 2007.

[4]

Z. Wang; L. Chang, "A DC voltage Monitoring and Control Method for Three

Phase Grid-Connected Wind Turbine Inverters",IEEE Trans. On Power

Electronics, Vol. 23, No.3, pp. 1118-1125, May 2008.

[5]

T. Yuki;H. Yoshikiro; K. Kosuke,

"Temperature and Irradiance Dependence of the I-V Curves of Various Kinds

of Solar Cells" International Photovoltaic Science & Engineering

Conference, Shanghai, China 2005

[6]

A. Moein, M. Pouladian, "WIH-Based IEEE 802.11 ECG Monitoring

Implementation", Proceedings of the 29th Annual International Conference

of the IEEE EMBS Cite Internationale, Lyon, France August 23-26,2007.

[7]

H. Zhao, X. Chen,K.H. Chon, "A Portable, Low-cost, Battery-powered

Wireless Monitoring System for Obtaining Varying Physiologic Parameters from Multiple

Subjects" , Proceedings of the 28th IEEE EMBS Annual International

Conference, New York City, USA, Aug 30Sept 3, 2006

[8]

H. Zhiqiang; Z. Wenxian; L. Jianke, "Research on High-Speed Data

Acquisition and Processing Technique", The Eighth International Conference

on Electronic Measurement and Instruments, ICEMI'2007

No comments:

Post a Comment