DIRECT TORQUE CONTROL OF BLDC MOTOR USING

FUZZY LOGIC IN LABVIEW

ABSTRACT

Brushless dc motors are widely used in many industrial applications due to

their high efficiency, high power density and ease of control. In this paper,

sensorless direct torque control (DTC) of bldc motor is implemented using fuzzy

logic. In actual DTC both torque and stator flux linkage is controlled. In the

proposed system, the control of stator flux linkage is avoided because every

commutation will cause the stator flux linkage decreasing dramatically and

sharp dip appears on the locus of the stator flux linkage every 60 electrical

degrees. The best way to control the stator flux linkage amplitude is to know

the exact shape of it, but it is considered too cumbersome in the constant

torque region. Therefore the amplitude of stator flux linkage can be considered

as a constant. The proper voltage vector selection is done using fuzzy logic

controller which improves the dynamic performance. The sensorless operation is achieved

by using a state observer. All the simulations were done in LabVIEW software of

virtual instrumentation.

Keywords—Brushless DC motor(BLDC), Direct torque control (DTC),

fuzzy Logic controller, stator flux linkage, voltage vector selection, state observer,

LabVIEW, virtual instrumentation.

INTRODUCTION

Permanent magnet Brushless DC (BLDC) motors are nowadays widely used in

industries such as HVAC industry, medical, electric traction, road vehicles, aircrafts,

military equipment, hard disk drive, etc. due to their high efficiency, high

power density, reliability and ease of control. Today there are basically two

types of instantaneous electromagnetic torque controlled ac drives used for

high-performance applications: vector and direct torque control (DTC) drives.

The vector control, the most popular method uses a decoupling control which

transforms the motor equations into a coordinate system that rotates in synchronism

with the rotor flux vector. The second method, Direct Torque Control (DTC) is a

form of hysteresis or bang-bang control to control torque (and thus speed) of

electric motors. The basic concept behind the DTC of ac drive, as its name

implies, is to control the electromagnetic torque and flux linkage directly and

independently by the use of six or eight voltage space vectors found in lookup

tables. The advantages associated with DTC are simplicity and high dynamic

performance, no vector transformation and faster torque response. The torque

ripple is the major problem associated with DTC (1-8).Various papers proposed

new methods for eliminating the problems associated with classical DTC. Some

papers proposed multilevel inverter in which there are more voltage space

vectors available to control the flux and torque and hence smoother torque can

be obtained

(2). Here more power switches are required which increases system cost and

complexity. In (6) and (11) two PI regulators are required to control the flux

and torque and they need to be tuned properly. In DTC,\ the stator flux is

estimated by integrating the back- EMF which should be reset regularly to

reduce the effect of the dc offset error. In papers (12), (13) dc offset is

eliminated by introducing low pass filters for estimating the stator flux

linkage. In this paper fuzzy logic is used for proper voltage vector selection.

Fuzzy logic can be considered as a mathematical theory combining multi-valued

logic, probability theory, and artificial intelligence to simulate the human

approach in the solution of various problems by using an approximate reasoning

to relate different data sets and to make decisions. It has been reported that

fuzzy controllers are more robust to plant parameter changes than classical PI

or controllers and have better noise rejection capabilities. The introduction

of fuzzy logic quickens the torque response and provides smooth torque. Hence

overall static and dynamic performance can be improved (7- 8).The torque and rotor

speed are obtained from the back-EMFs, which are estimated using a state observer.

In this paper, all simulations had done in the LabVIEW (Laboratory Virtual

Instrument Engineering Workbench) software. In comparison with the other software

tools, the simulation with LabVIEW provides easy debugging features and user friendly

environment. The conventional six step control of BLDC motor is also simulated.

The simulation results shows that the proposed DTC scheme using fuzzy logic has

good control performance, compared with conventional method.

BLDC MOTOR DRIVE MODEL

The assumptions made for modeling BLDC motor are

1) The motor’s stator is a star wound type.

2) The motor’s three phases are symmetric, including their resistance,

inductance and mutual inductances.

3) There is no change in rotor reluctance with angle due to non-salient

rotor.

The BLDC motor is modeled in the stationary reference frame using phase

currents, speed, and rotor position as state variables. The BLDC motor is modeled

as

Where Va,Vb,Vc, Ia,Ib,Ic, and Ea,Eb,Ec are the stator voltages, stator

currents and back-EMFs of all the three phases respectively, R and L are the

resistance and inductance of stator phase winding respectively and p is the

differential operator(d/dt).

The generated electromagnetic torque is given by

where ω is the speed.

The induced back-EMFsis of trapezoidal shapes and can be written as

Ea = fa(θ)λω (3)

Eb = fb(θ)λω (4)

Ec = fc(θ)λω (5)

wherefa(θ), fb(θ), fc(θ) are functions having trapezoidal shapes as

back-EMFs and λ is the back-EMF constant.

BLDC – DTC SYSTEM

A conventional six-switch 3-phase inverter fed BLDC motor in two-phase

conduction mode, as show in Fig. 1.

Fig. 1. An inverter driving BLDC motor

The primary voltages Van, Vbn, and Vcn are determined by the status of the

six switches, S1, S2, S3, S4, S5 and S6. There are six nonzero voltage

vectors:- V1(100001), V2(001001), V3(011000), V4(010010),V5(000110), V6(100100)

and one zero voltage vector V0(000000). The six nonzero voltage vectors are 60 degrees

apart from each other as in Fig. 2.

Fig. 2. Stator flux linkage space vector representation

The basic principle of direct torque control (DTC) is to choose the

appropriate stator voltage vector out of eight possible voltage vectors

according to the difference between the reference and actual torque and flux linkage

so that the stator flux linkage vector rotates along the stator reference frame

trajectory and produces the desired torque. The stator flux is controlled by

properly selecting voltage vectors and hence the torques by stator fluxes

rotation. The faster torque response is achieved by increasing the stator vector

rotation speed. In this proposed paper (14), the DTC of a BLDC motor drive

operating in two-phase conduction mode is simplified by controlling only torque

and by intentionally keeping the stator flux linkage amplitude constant by

eliminating the flux control in the constant torque region. Since the flux control

is removed, fewer algorithms are required for the proposed control scheme.

There is no need to control the stator flux linkage amplitude of a BLDC motor

in the constant torque region due to the sharp changes which occur every 60

electrical degrees and hence the flux control is quite difficult. Therefore the

stator flux linkage amplitude is kept almost constant on purpose and only torque

is controlled. Also the zero voltage vector suggested in to decrease the electromagnetic

torque could have some disadvantages, such as generating more frequent and larger

spikes on the phase voltages that deteriorate the trajectory of the stator flux-linkage

locus, increase the switching losses, and contributes to the large common-mode

voltages that can potentially damage the motor bearings. To overcome these

problems, a new simple voltage space vector look-up table is developed. The rotating

speed of the stator flux linkage can be controlled easily by selecting proper voltage

vector. For instance, in the region I of Fig. 2, for counterclockwise operation,

if the actual torque is bigger than the reference, voltage vector V5 is

selected to keep flux linkage rotating in the reverse direction. The torque

angle decrease as fast as it can, and the actual torque decrease as well. Once

the actual torque is smaller than the reference, voltage vector V2 is selected

to increase torque angle and the actual torque. Hence the region of the stator

flux linkage is known, selecting proper voltage vector can reach fast torque

control. The new simplified switching table is as follows:

TABLE I

Here the ET represents the error in torque and is determined by the

difference between reference torque and estimated torque. The value ‘0’ or ‘1’

stands for that the estimated value is smaller or bigger than the reference

value respectively. I, II, III…, VI denotes the stator flux linkage region.

BLDC-DTC SYSTEM USING FUZZY LOGIC

In the past decade, fuzzy logic control techniques have gained much

interest in many applications. Fuzzy Logic is a form of many-valued logic or probabilistic

logic. It deals with reasoning that is approximate rather than fixed and exact.

In traditional logic theory, have two valued logic-true or false (0 or 1). It

has been extended to handle the concept of partial truth, where the truth value

may range between completely true and completely false. They have a real time

basis as a human type operator, which makes decision on its own basis. In the proposed

BLDC-DTC system the fuzzy logic controller is used for selecting the proper

voltage vector. It involves basically three steps:-

A. Fuzzification

The fuzzification is the process of a mapping from input to the

corresponding fuzzy set in the input universe of discourse. There are two

inputs to the fuzzy logic controller: - Torque error (ET) and angle information.

Output of the fuzzy logic controller is proper voltage vector (V1 to V6).Torque

error (ET) is divided into four fuzzy subsets with the linguistic value {PB,

PS, NS, NB} and its universe of discourse is [-0.1 0.1]. Flux linkage angle

(Angle) is divided into six fuzzy subsets {A1, A2, A3, A4, A5, A6} and its universe

of discourse is [-π π]. The output Space voltage vector (V) is divided into six

singleton fuzzy subsets {V1, V2, V3, V4, V5, V6}. Membership functions of

twofuzzy input variables (ET and Angle) and one fuzzy output variables (Vi) are

triangle type as shown in Fig.3.

(b) Membership function of flux linkage angle

Fig. 3. Membership functions of the fuzzy controller

B. Rules and fuzzy reasoning

Fuzzy control rules are expressed in the IF-THEN format as IF ET is Ai and

Angle is Bi, THEN V is Vi Where Ai, Bi, Vi denote fuzzy sets. The entire fuzzy rules

expressed as a table as shown in the table II

TABLE II

Mamdani’s Min-Max method is employed in the fuzzy reasoning.

C. Defuzzification

The defuzzification is not required in the controller because output of the

fuzzy controller is just six singleton fuzzy subsets which are the actual PWM

voltage vector sequence composed of only seven different states, and these

states could be directly used as the successor of the fuzzy rules.

SENSORLESS OPERATION USING BACK-EMF OBSERVER

In BLDC motor, the electromagnetic torque can be estimated directly from

the back-EMF and the speed.

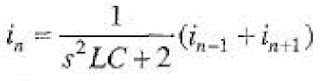

Here in this proposed method, an observer is used to estimate the back-EMF

waveform. By choosing α- axis and β-axis stator currents and back-EMFs as the state-variables,

the following state equations can be obtained

ẋ = Ax + Bu(6)

y = Cx(7)

Where x = [ia, ib, ea, eb]T is the state vector, u = [ua, ub]T is the input

vector, y = [ia, ib]T is the output vector, and

e^= K (y -y^)(8)

Where e^ = [ea, eb]T is the back-EMF

vector, K= diag(k1, k2) is the gain matrix, k1 and k2 are positive constants. The

relation between the rotor speed and amplitude of the back-EMF is given by

E = PKeω(9)

Where P is the number of pole pairs, Ke is the back- EMF constant of the

motor, E is the amplitude of every phase back- EMF. The estimated speed is

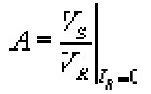

given by

The estimated rotor position is obtained by θ

LabVIEW IN VIRTUAL INSTRUMENTATION

LabVIEW (Laboratory Virtual Instrumentation Engineering Workbench) is a graphical

programming language that uses icons instead of lines of text to create

applications.LabVIEW programs are called virtual instruments, or Vis, because

their appearance and operation imitate physical instruments, such as oscilloscopes

and millimeters. Every VI uses functions that manipulate input from the user interface

or other sources and display that information or move it to other files or

other computers. LabVIEW object oriented programming uses concepts from other

object oriented programming languages such as C++ and Java, including class,

structure, encapsulation, and inheritance. We can use these concepts to create

code that is easier to maintain and modify without affecting other sections of

code within the application. We can use object oriented programming in LabVIEW

to create user-defined data types. That is different types of physically

existing systems can be simulated using this software. Here in this project we are

using this software to design the control schemes of hybrid electric vehicle.

The advantage of the LabVIEW software over other simulating software is that a

wide range of hardware components are available which are helpful in testing as

well as implementation of various applications that we develop in this software.

In this proposed paper all the simulations had done in LabVIEW software.

BLOCK DIAGRAM OF SENSORLESS FUZZY BLDC-DTC SYSTEM

The block diagram of a sensorless fuzzy based BLDC DTC system is shown in

Fig. 4. In the proposed system, there is an inner torque loop and outer speed loop.

The reference torque is obtained from the speed controller and is limited at a

certain value. Both voltages and currents are measured and then transformed

into the stationary reference frame alphabeta components in the system.A

back-EMF observer provides the estimated back-EMF. A fuzzy logic controller

generates the switching signal which drives the inverter.

Fig. 4. Block diagram of proposed fuzzy BLDC-DTC system

SIMULATION RESULTS

All the simulations had done in LabVIEW software.The parameters of the BLDC

used in the system are listed in the table 3.

TABLE III

BLDC MOTOR SIMULATION PARAMETERS

Fig. 6 shows the performance comparison between the conventional PWM method using the sensor and the proposed method. The torque ripple and the current ripple are much less, compared with the PWM scheme. A load torque of 2 Nm is applied. The figure shows the response performance of the proposed sensorless drive at 1000 rpm. Although the small deviation occurred after injecting the load, the performance is generally good.

Fig. 5. Simulation results of the proposed fuzzy based

DTC scheme

Fig. 6. Simulation results of conventional PWM method

CONCLUSION

The proposed two-phase conduction mode for DTC of BLDC motors is introduced

as opposed to the conventional PWM control in the constant torque region. Much

faster torque response is achieved compared to conventional PWM current and especially

voltage control techniques. It is also shown that in the constant torque region

under the two-phase conduction DTC scheme, the amplitude of the stator flux

linkage cannot easily be controlled due to the sharp changes and hence it is

kept constant. The proper voltage vector selection is done using fuzzy logic

controller which improves the dynamic performance. The sensor less operation is

achieved by using a state observer which also improves the performance. Fuzzy

controller is virtually created in LabVIEW and utilized to implement the

algorithm.

Speed control of BLDC motor is achieved using virtual instrumentation. This

proposed method controls the speed for various ranges. The simulation results

show that the proposed scheme has good estimation performance in low and high

speed range and good control performance, compared with the conventional PWM

method.

REFERENCES

[1] Y. Liu, Z. Q. Zhu, D. Howe, ”Direct torque control of brushless

DCdrives with reduced torque ripple,” IEEE Trans. Ind. Appl., vol. 41, no.2, pp.

599-608, 2005.

[2] L. Zhong, M. F. Rahman, W. Y. Hu, K. W. Lim, ”Analysis of DirectTorque

Control in Permanent Magnet Synchronous Motor Drivers,” IEEETrans. on Power

Electronics, vol. 12, no. 3, pp. 528-535, 1997.

[3] Won Chang-hee, Song Joong-Ho,lck Choy, ”Commutation torque

ripplereduction in brushless DC motor drives using a single DC current sensor,”

Power Electronics, IEEE Transactions on, vol. 19, no. 2, pp, 312-319, 2004.

[4] S. J. Kang, S. K. Sul, ”Direct torque control of brushless DC motorwithnon-ideal

trapezoidal back-EMF,” IEEE Trans. Power Electron., vol. 10, no. 6, pp.

796-802, 1995.

[5] S. K. Chung, H. S. Kim, C. G. Kim, and M. J. Youn, “A new instantaneoustorque

control of PM synchronous motor for high-performance direct-drive applications,”

IEEE Trans. Power Electron., vol. 13, no. 3, pp. 388–400, May 1998.

[6] M. Ehsani, R. C. Becerra, ”High-speed torque control of brushlesspermanent

magnet motors,” IEEE Trans. Ind. Electron.. vol. 35, no. 3, pp. 402-406, 1988.

[7] Do Wan Kim, Ho Jae Lee, and Masayoshi Tomizuka, “FuzzyStabilization of

Nonlinear Systems under Sampled- Data Feedback: An Exact Discrete-Time Model

Approach,” IEEE Transactions on Fuzzy Systems, Vol. 18, No. 2, Apr.

2010, pp: 251 – 260.

[8] Zdenko Kovaccic and Stjepan Bogdan, “Fuzzy Controller designTheory and

Applications”, © 2006 by Taylor & Francis Group. international, 2002.

[9] D. Grenier, L. A. Dessaint, O. Akhrif, J. P. Louis, “A parklike transformationfor

the study and the control of a nonsinusoidal brushless dc motor,” in Proc.

IEEE-IECON Annu. Meeting, Orlando, FL, Nov. 6-10, 1995, vol. 2, pp.

836–843.

[10] K. Y. Cho, J. D. Bae, S. K. Chung, and M. J. Youn, “Torque harmonicsminimization

in permanent magnet synchronous motor with back-EMF estimation,” in Proc IEE

Elec. Power Appl., vol. 141, no. 6, pp. 323–330, 1994.

[11] C. Lascu, I. Boldea, and F. Blaabjerg, “A modified direct torque

control forinduction motor sensorless drive,” IEEE Trans. Ind. Appl., vol. 36,

pp. 122–130, Jan./Feb. 2000.

[12] B. K. B. And and N. R. Patel, “A programmable cascaded low-pass

filter-basedflux synthesis for a stator flux-oriented vector-controlled

induction motor drive,” IEEE Trans. Ind. Electron., vol. 44, pp. 140–143, Feb.

1997.

[13] M. F. Rahman, Md. E. Haque, L. Tang, and L. Zhong, “Problems

associated withthe direct torque control of an interior permanent-magnet

synchronous motor drive and their remedies,” IEEE Trans. Ind. Electron., vol.

51, pp. 799–809, Aug. 2004.

[14] Y. Liu, Z. Q. Zhu, and D. Howe, “Direct torque control of brushless dc

driveswith reduced torque ripple,” IEEE Trans. Ind. Appl., vol. 41, no. 2, pp.

599–608, Mar./Apr. 2005.

[15] W. S. H. Wong, D. Holliday, “Constant inverter switching frequency

directtorque control,” in Proc. IEE-PEMD Annu. Meeting, Bath, UK, Jun. 4-7,

2002, pp. 104–109.